Founded in early 2007 by the mother-daughter duo of Joan and Emily Sugihara as a producer of a simple reusable bag, BAGGU has come a long way in its four years of life. The Williamsburg-based company has quickly expanded out from its original collection―the ripstop nylon bag based off the classic plastic grocery store bag, which was offered in eight colors―to a formidable and varied line of six different items that come in dozens of colors, prints, and washes.

Anthem recently swung by the office Emily shares with Ellen van der Laan―a childhood friend who came on board as creative director in 2008―to chat about their origins, their designs, their creative processes, and their inspirations. Read on for the full and in-depth conversation!

BAGGU is sold online at baggu.com and at Pas de Deux at 328 E. 11th St.

Alright, so let’s just start at the beginning. Tell me about how BAGGU came into existence.

Emily Sugihara: Okay, so my mom and I started BAGGU together. I live in New York and she lives in San Diego with my dad and my little brothers, who’re now in college. It began as basically a sewing project―the two of us always made stuff together and we wanted to make reusable bags for ourselves since we couldn’t find anything interesting. So we designed the standard BAGGU―which is what we launched the company with, in eight different colors―and during the process of making prototypes, we were sort of thinking of it as a product as opposed to just a thing we were making. We thought a lot about how we could get the best yield out of our material (how to minimize waste) and create something easy to massproduce.

Once we had a design we thought was interesting, we started talking to factories, thinking, “Oh, we’ll find a sewing factory in San Diego and make a hundred [bags] and see if our friends like them.” But the more research we did, the more it became apparent that one of the major hurdles for people using reusable bags was price―like, both our moms go to the grocery store once a week and shop for the family and they need a lot of bags! So we wanted to make something affordable that people would use, which priced us out of making stuff in the U.S. Then we started looking at manufacturing overseas, and, of course, you can’t order, like, a hundred bags [in that case]. I think our first order was for 40,000 bags, which now is nothing, but at the time, we were like, Holy crap―what are we going to do with all these bags?

So, that immediately changed it from a hobby to a [business venture]. I’d been working as a fashion designer and I left my job, deciding BAGGU was what I wanted to put my energy into. Around that time―when we were trying to figure out how we were going to make the bags―Ellen [van der Laan] and I―we’ve known each other since we were three and went to preschool together, and she’s a really talented graphic designer―got together and I showed her the stuff I made and asked [for her input]. She’d be like, “Do you just want me to do that for you?” [Laughs] So, Ellen started coming over after work at night. She did the logo [and made the business cards]. We picked the original eight colors together, using a Pantone color book that we borrowed from another friend who probably stole it from their work for the night. It was very scrappy. [Laughs] And very reactive, in the early days. After about a year, Ellen quit her job and came on board full-time.

What were you doing beforehand?

Ellen Van Der Laan: I was working at M·A·C Cosmetics, doing in-store graphics and design. We were both in Brooklyn.

E.S.: There was a brief―though not significant―interlude during which I was in San Francisco. Our warehouse is still there, actually. I was living there when it got to the point where I could no longer physically ship all the boxes that had to be shipped.

You couldn’t do all 40,000 bags on your own?

E.S.: Actually, my mom and my 15-year-old brother shipped that whole first order! Everyone really pitched in and made it work… and there were a ton of late nights.

We had this big order for Amazon.com that we had to do and they needed it packaged in this really specific way, and we didn’t do packaging in the beginning because we were trying to replace packaging. (We now have hang-tags, though, since we work with big retailers and you can’t sell a product in a store with no labeling at all.) But Amazon.com required that we shrink-wrap everything to a piece of cardboard… so, one night, my mom and little brother stayed up all night shrink-wrapping the bags to pieces of cardboard. There was a lot of crazy stuff like that.

Outside of enjoying making stuff with your mother, was there anything else that drew you specifically to making bags? Going from fashion designer to bag designer seems like a bit of a jump.

E.S.: Well, making anything is kind of the same. But… I always knew I wanted to have a small business. Well, actually a large business [Laughs]―we’re getting there. Like, all my projects since I was a kid… and the funny T-shirt company I made with my college roommate… there’s always been this weird sort of entrepreneurial thing to all of it. I was sort of biding my time at my job until the right thing came along. When we came up with the bag design, the timing was really good―at the time, no one really knew what a reusable bag was and we had to always explain it. Right when we launched, [that’s when reusable bags started to get big].

Well, and now even cheap, generic ones are sold at grocery stores… which is probably good for you guys.

E.S.: It’s great for us.

When we were coming up with our pricing model at the beginning, we were like, Okay, we should make $2 bags because that’s really affordable. The problem with that is if you make bags [that cheap], they’ll inevitably be of a bad quality since you need to produce them for, like, 30 cents. Also, people don’t value things when they’re that cheap, so you just get people buying one every time they’re at the grocery store, even though they have, like, 50 in the back of their closet. So we wanted to have a price-point that was expensive enough to ensure the quality was good and so that [the consumer] would value it enough to not just replace it. We go for a value price-point with everything we make.

What’s the story behind the design of the main bag?

E.S.: It’s based on a plastic grocery store bag, so it’s a really simple shape with a gusset at the bottom, which means it lays flat when it’s full. We basically just took the grocery store bag and elongated the handle so you could put it over you shoulder. We were both thinking of New Yorkers when designing the bag and wanted to make something you could carry comfortably for 10 blocks, between your house and the grocery store.

E.V.D.L.: There’s only one seam on the bottom, which makes it easier to carry, and most reusable bags have two.

E.S.: We triple-stitched the bottom seam and have actually never had a blowout. They hold 50 pounds―they’re crazy strong.

E.V.D.L.: And the pouch is made from the cutout of the one piece [we use to make the bag].

E.S.: It’s the simplest way we could come up with to make a bag with these functions.

The leather bag is a really similar shape… how did you design those?

E.S.: Yeah, it is. In the nylon, we have three sizes―the medium, the baby, and the big―in the leather, we have two―the medium and the baby, because cows aren’t big enough to make the big one. [Laughs]

When did you decide to branch out?

E.S.: For the first year, we just had [the shopping bag]. Then we added colors and, eventually, prints. In the second year, we started adding more sizes, and in the third year, my mom mailed us a canvas bag that was basically what our duck bag is now. It had a weird Post-it note attached that said, Hey, I made this―it could be like the paper bag to the plastic bag!

E.V.D.L.: It was so cool, to get this beautiful bag out of nowhere.

E.S.: So then we started working in recycled cotton, which was our first fabric outside of the ripstop nylon. Then, about six months after that, she showed up in New York, and she had made a sort of duck bag-style backpack that she was just wearing without saying anything about. She’s kind of shy. [So we started making that] and coincidentally got on the backpack trend pretty early.

The backpacks are really cool and there are for sure not that many options around that are both value priced and of a good quality. Anyway―there’s other stuff you make, too.

E.S.: Yeah, so we have the canvas bags… and we also started making the zip sets about a year ago. Those are just little, really simple zipper bags that come in sets. We wanted something that would help organize your purse.

E.V.D.L.: We were also thinking about making something to replace Ziploc bags, and we tried all these different options―

E.S.: We were thinking food-use bags…

E.V.D.L.: Yeah, and we decided that didn’t really seem like the direction our company was going. Also, ripstop nylon didn’t really seem ideal for food.

E.S.: Putting food in cloth bags in general is… it’s a big mental leap for most people.

E.V.D.L.: But yeah, I think that was part of it. We were thinking about little bags and realized they’re useful for so many other things, like packing or shoe bags, cosmetic bags…

I guess that’s the bigger question: how are you continuing to respond to the market and further grow your catalogue? How do you figure out what to make next while staying true to yourselves?

E.S.: I think [our process] is very trial and error. We’re always asking ourselves what direction we’re going in. I think by year two, we realized that the grocery thing wasn’t really where we were going; we were going more in the accessories direction. In the beginning, we thought that grocery stores would buy these bags and that we’d be a company that sold to places like Whole Foods. But, like… an $8 bag seems really cheap at J. Crew and really expensive at a grocery store―and that isn’t where people think to buy things they’ll have for a while. We still want to make everything in the most eco-friendly way we can, but we found our home in fashion and accessories.

E.V.D.L.: I think we’ve tried to stay very product-based in that we always want to make things that we would want to carry. We’ve never set out saying, “Oh, this is a really great market that we should go after―let’s make this.”

E.S.: It’s more like… “Oh, do you know what would be really cool that I can’t buy one of right now?”

And you’re not making seasonal, so you sort of have to avoid that… transcend the trends…

E.S.: Exactly. We also try to just be really basic with the stuff we’re making… to make stuff that people are going to want for a while.

E.V.D.L.: Just the idea of a bright color―I think that’s appealing to people who are young and in our demographic. And people everywhere like to pick the colors of their bags…

Actually, how do you address the pattern designs? Not just the colors, but also the graphic elements?

E.V.D.L.: The only seasons we really keep to are the big buying seasons―the trade shows that happen in the summer for holiday and the trade shows that happen in the winter for spring. So we have these, like, twice a year self-imposed deadlines, and every time we make a purchase order, we’re thinking about if we want new patterns. I oversea that. In the same way as the colors, I’m always thinking about making a print that I’m going to like, that the people in the office will like, that a sort of fashion-y demographic will like… but also, the last thing I think about in my head is, Is my mom going to like this? And if I think she won’t, then it’s probably not the right thing for us. I think our designs should be classic enough to go across trends. We don’t want to make anything that’s super-trendy.

E.S.: We like stuff that we interpret as being edgy and fashion-y, but that our moms see as, like, being reminiscent of a shirt they had in the 80s. Like, the shapes print we think is cool, but to our parents, it looks sort of southwestern… or like an ethnic print!

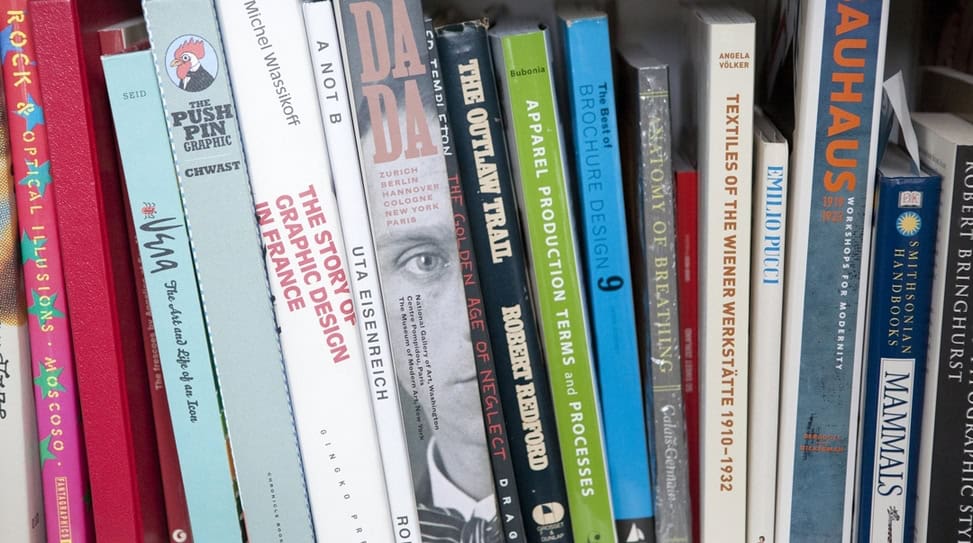

What kind of design background do you have, Ellen? What inspires you?

E.V.D.L.: I’m a big 60s and 70s music nerd, and I think that the big graphics and the look in general of that time really influenced me a lot. Like, when I think of Yoko Ono, it’s those graphics I think of. Along the same lines, I really love design that looks basically generic; things that almost don’t look designed.

E.S.: I think that’s where our taste really intersects: generic minimalism.

E.V.D.L.: My weird 70s obsession has some of that in there… like… think about The White Album. It’s sort of along those lines.

E.S.: I think if it was either one of us doing it on our own, everything would look way different, but since it’s the two of us trying to find things that are timeless…

I’m curious about your international reception. Do you notice any big difference between markets?

E.S.: With our international business, we work with distributors. So, we’ll work with one company in another country who will buy large-scale from us―we’ll ship to them directly from the factory―and they retail [that product] directly to stores. I think a lot of it [boils down to] the taste of the distributor we’re working with as they’re definitely buying stuff that sells, but they’re also buying stuff according to their tastes. In general, they’ll carry all our styles, but only half the colors.

E.V.D.L.: And we also make sure the distributors have our aesthetic sense in mind… that they can communicate what our brand is, and that the other products they carry are things we think are cool.

Do you have any new ideas forthcoming? Any big plans?

E.S.: I think our forward mission is that we want to make environmentally-friendly, well-made versions of almost everything. We’re in the early concept stages of some non-bag things. Everything we make will be basic and season-less―we never want to make something that’s only cool for three months, because that means it’s going into the landfill on the fourth month. Or to Beacon’s Closet and then to the landfill.

Are you actively pursuing eco-friendly awareness programs of any sort or are you just producing these eco-friendly products and leaving it at that?

E.S.: Well, we started with reusable bags, which are eco-friendly in and of themselves. But when you make an eco-friendly product, people hold you to a different standard.

E.V.D.L.: Yeah, like, How dare you make bags in China!?

E.S.: But you can’t do everything. Like, we could make our bag in the U.S., but it’d retail for about $40 and we wouldn’t be selling as many of them, so we wouldn’t be making as big an impact on reducing plastic bag consumption as we do now.

Also, everyone defines “green” differently. The fabric we use right now is infinitely recyclable. Paper you can only recycle so many times because the fiber eventually breaks down―cotton’s like that, too―but the nylon we use is a closed-loop product. In reality, most customers don’t recycle stuff. They can send bags back to us and we’ll recycle for them, but most people don’t do that at the end of its usefulness. So we try to make something that lasts as long as possible, and when it’s eventually disposed of, it takes up as little space as possible in a landfill.

E.V.D.L.: I think it was important to us to stay true to our idea of being environmentally responsible… but acknowledging that the only way to catch on is to be financially viable at the same time.

E.S.: We like setting an example of being an environmentally-conscious, woman-owned business that’s super profitable and doing great. Other people can do this, too! You can make money and be socially-conscious as well!

E.V.D.L.: And we’re very careful about the factories we work with. We have third parties audit all of them―

E.S.: Yeah―because we want to set the example of doing socially-responsible manufacturing overseas. Because that’s where the manufacturing is happening. If we can enforce good labor standards over there, then that’s a good contribution.

E.V.D.L.: And when we can, we’ll do things domestically. Our leather is sourced from South America, but our tannery is upstate and the bags are sew in New York City. That’s a really fun project.

A Conversation with Luke Kirby

A Conversation with Luke Kirby Q&A With Philip Lauer

Q&A With Philip Lauer

No Comments